How to save money

and time on your emergency lighting system

Whether you manage, install, design, or maintain emergency lighting systems, cost is an important consideration.

Most of the time, investing in a new system for your building facility comes down to balancing two things: function and budget. Your emergency lighting system needs to keep your building safe and compliant, and should be high quality, efficient, long-lasting, and user-friendly. But at the same time, you want to avoid spending more than you need to on installation, testing, and maintenance.

Fortunately, if you know what to look for, you can have a world class emergency lighting system and save money. (It’s like having your cake and eating it, too!)

The first thing you need to know is where your money goes when you purchase and manage an emergency lighting system.

Emergency lighting systems: what do you have to pay for?

Emergency lighting systems have upfront and ongoing costs, from equipment and installation to testing and compliance.

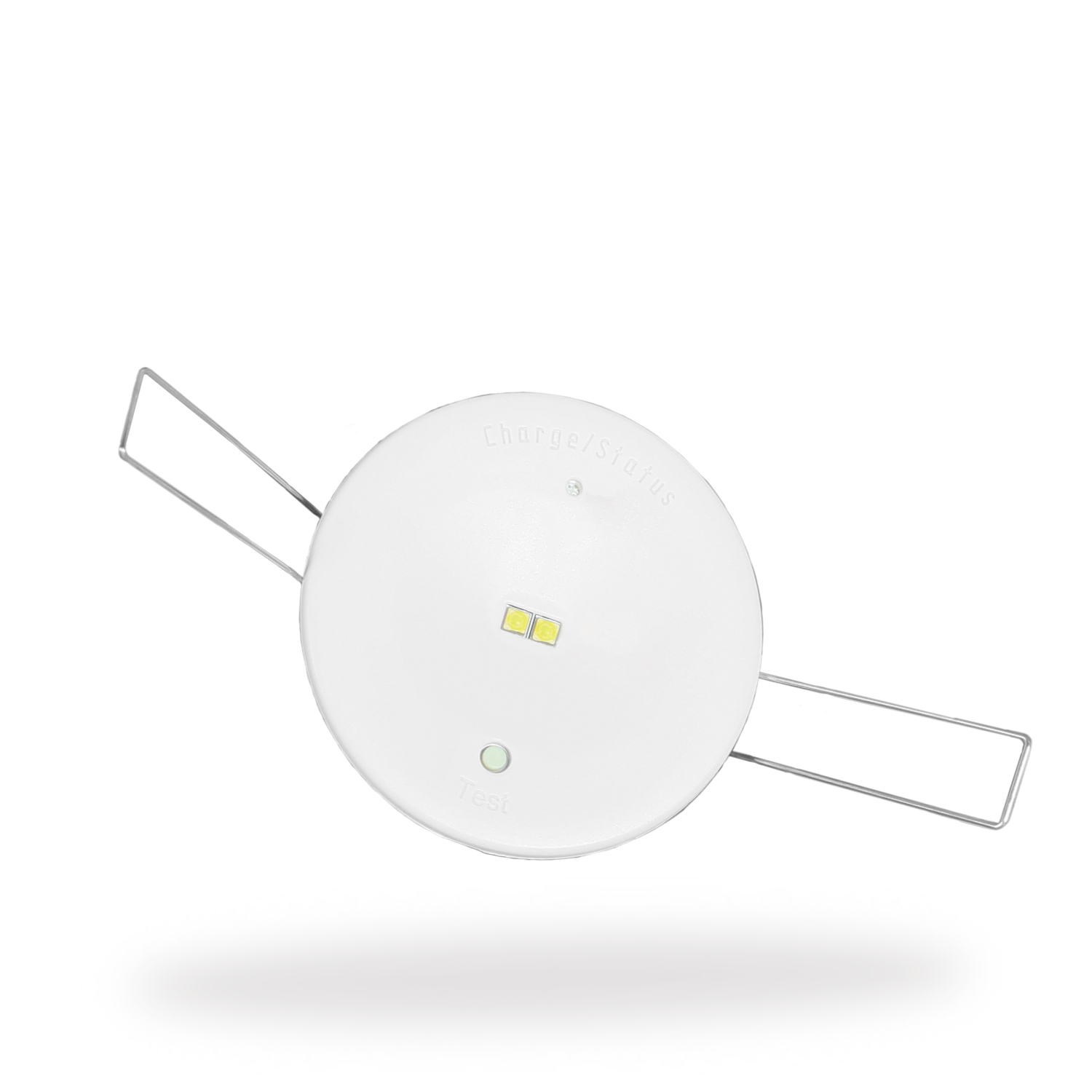

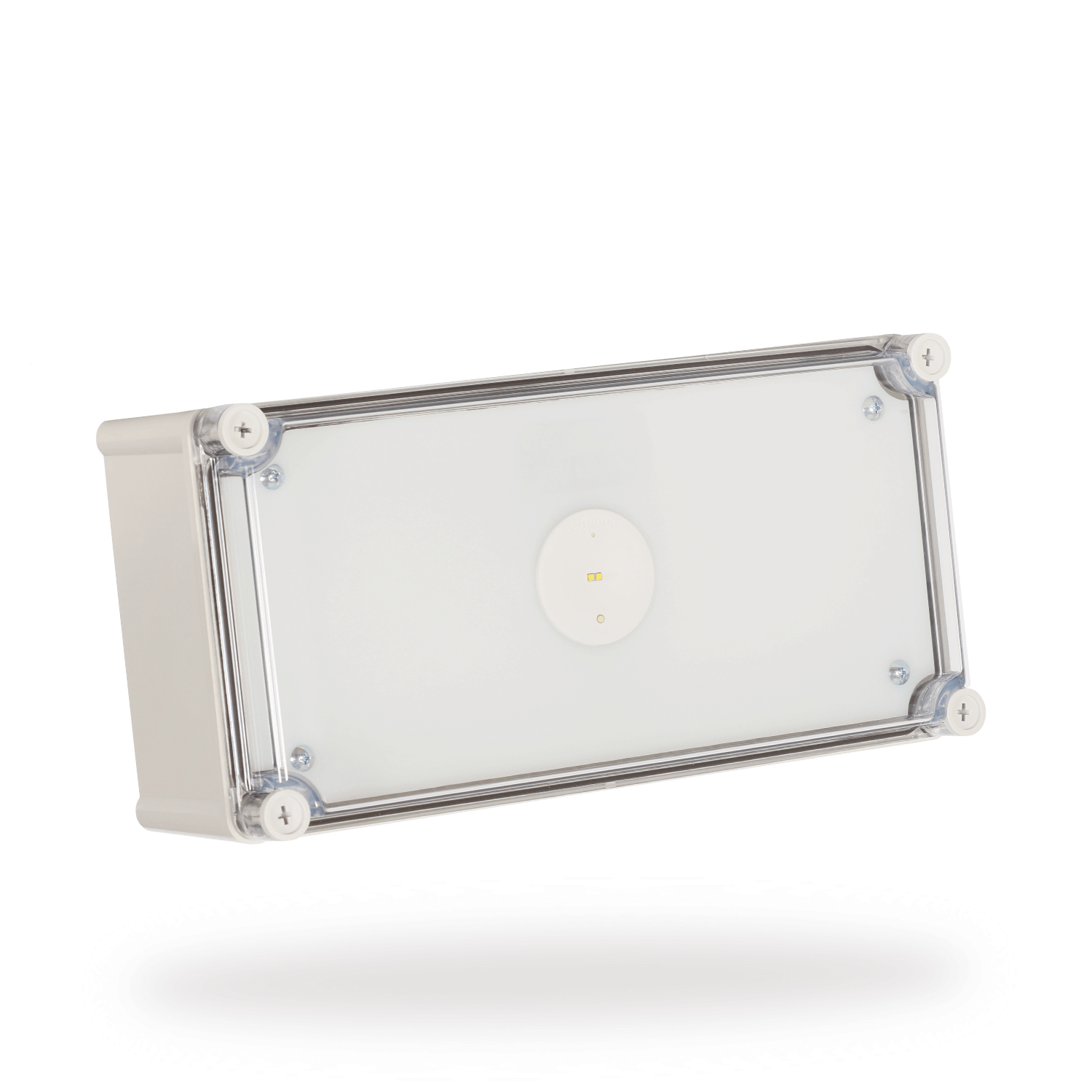

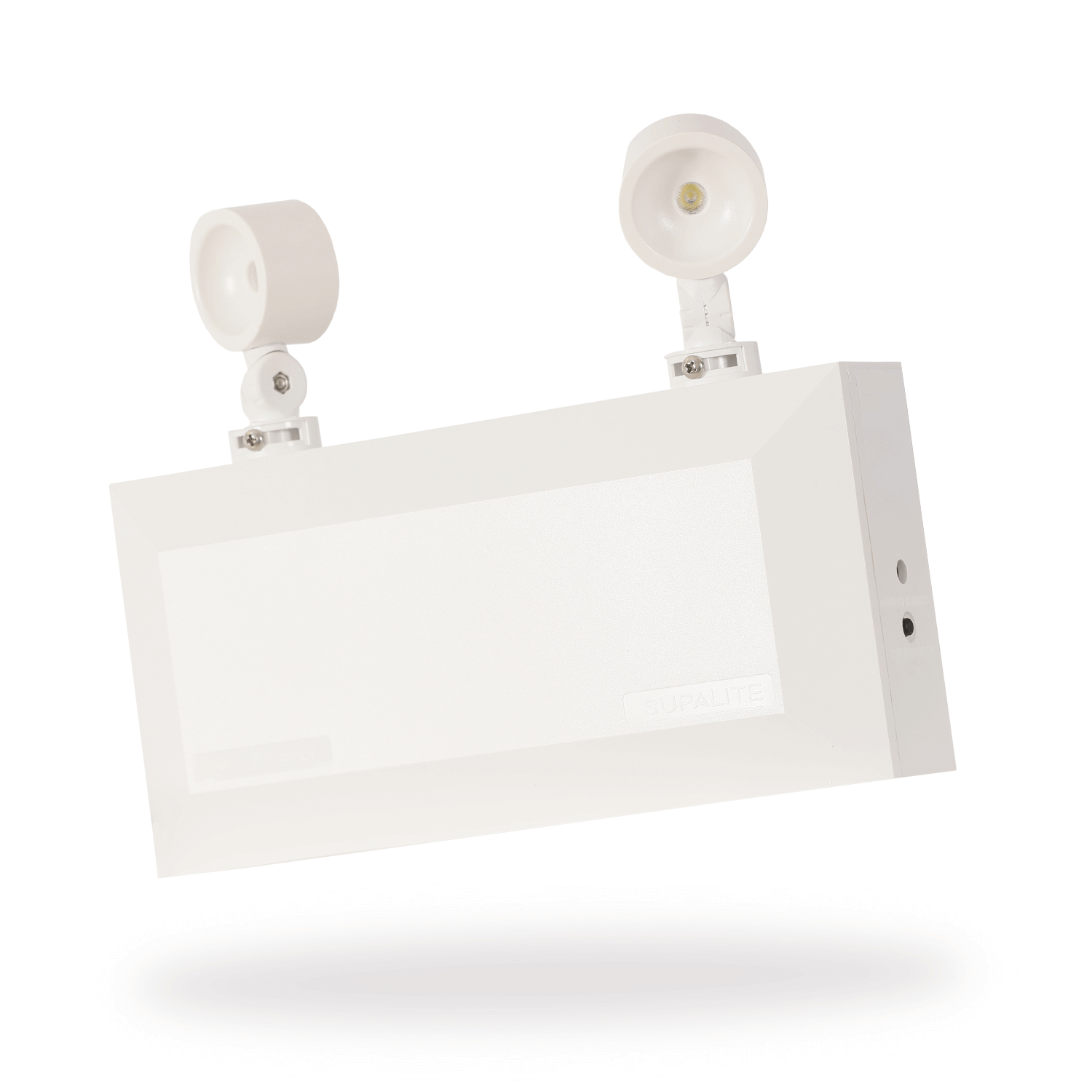

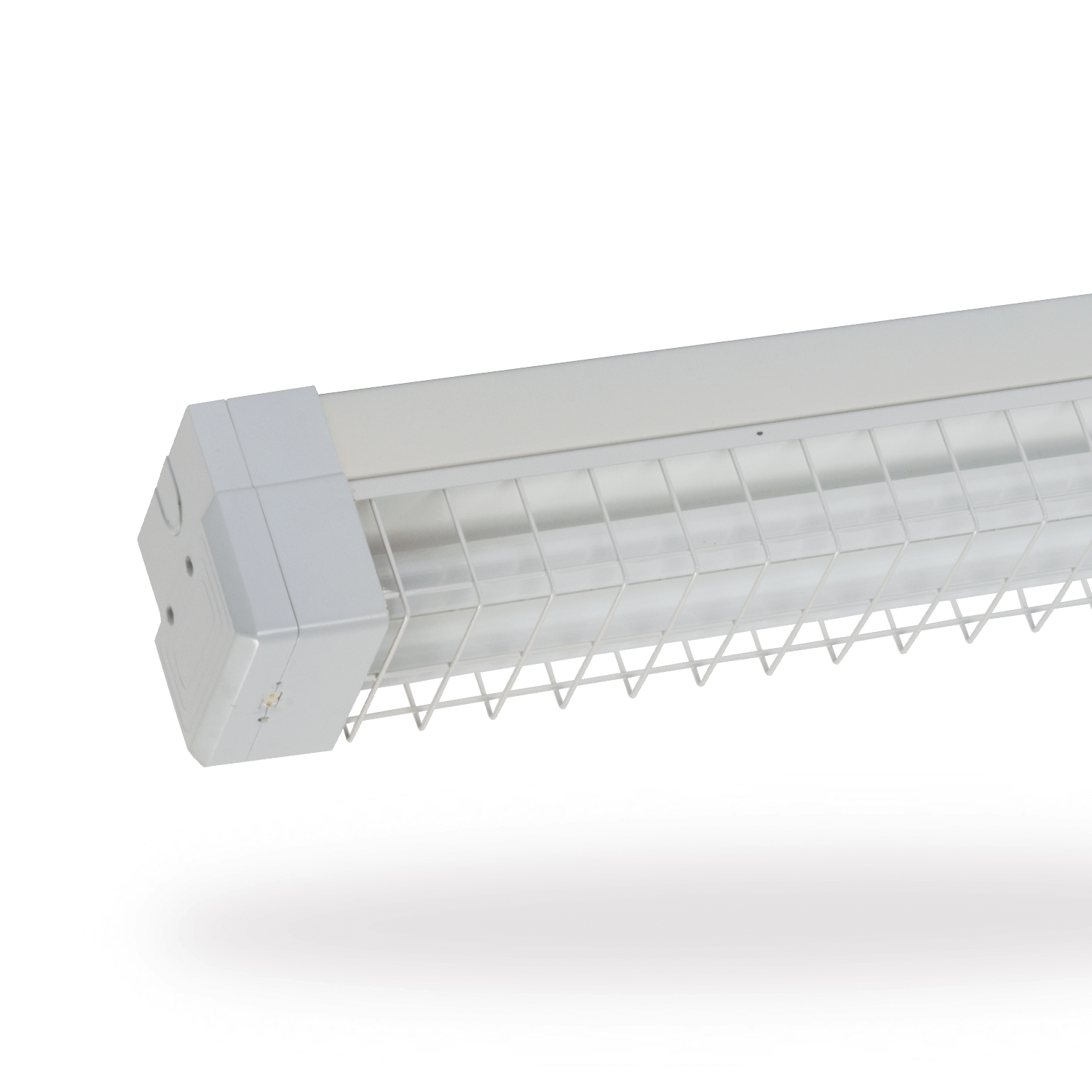

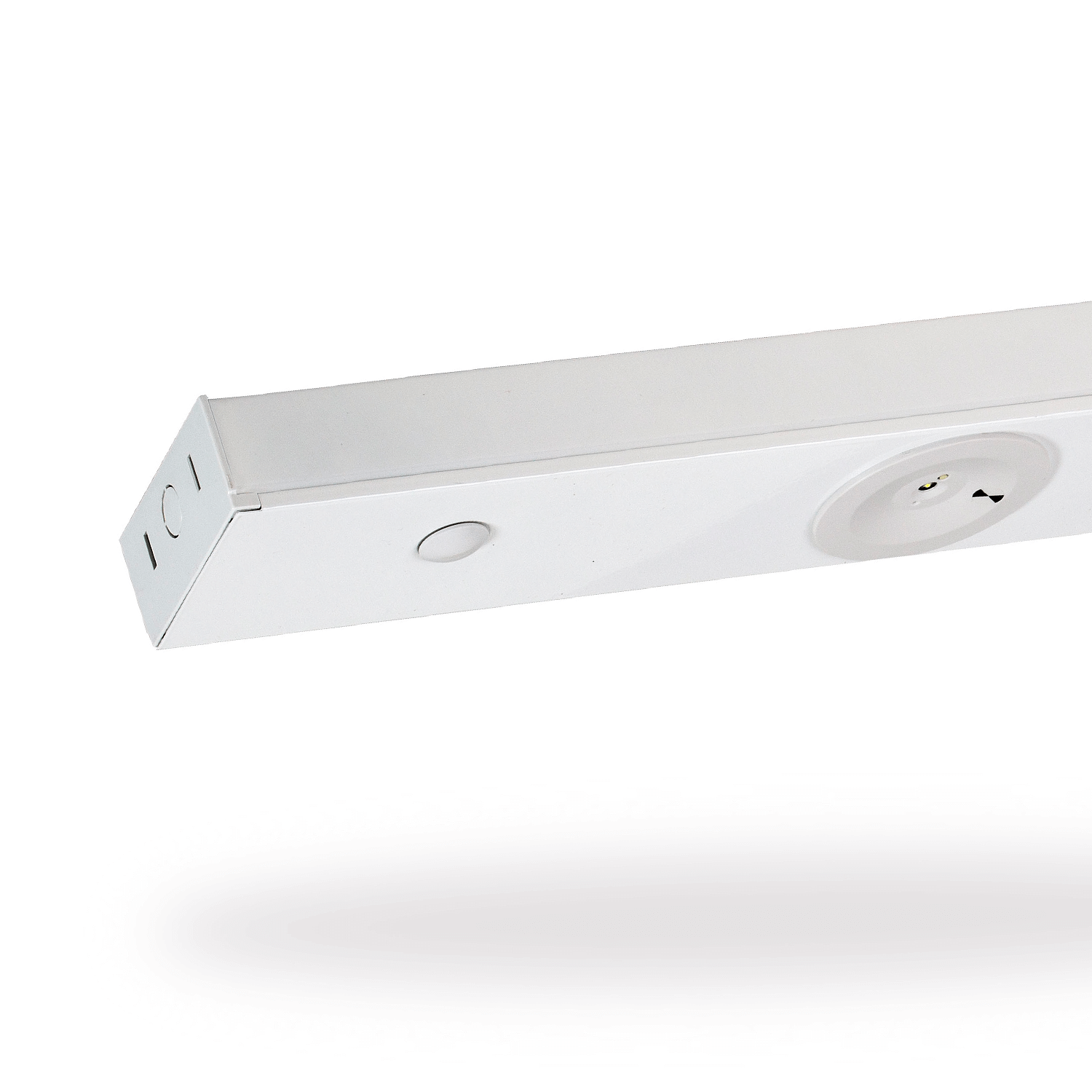

Equipment

The initial cost of your system comes from purchasing the equipment. That includes the lights themselves and whatever backbone you need, like data cables, controllers, routers, ancillary devices, and computer systems. Some systems require more backbone, which drives up the cost of your equipment. Other systems require just a few controllers and are connected wirelessly, which could mean a lower cost to purchase and install the equipment.

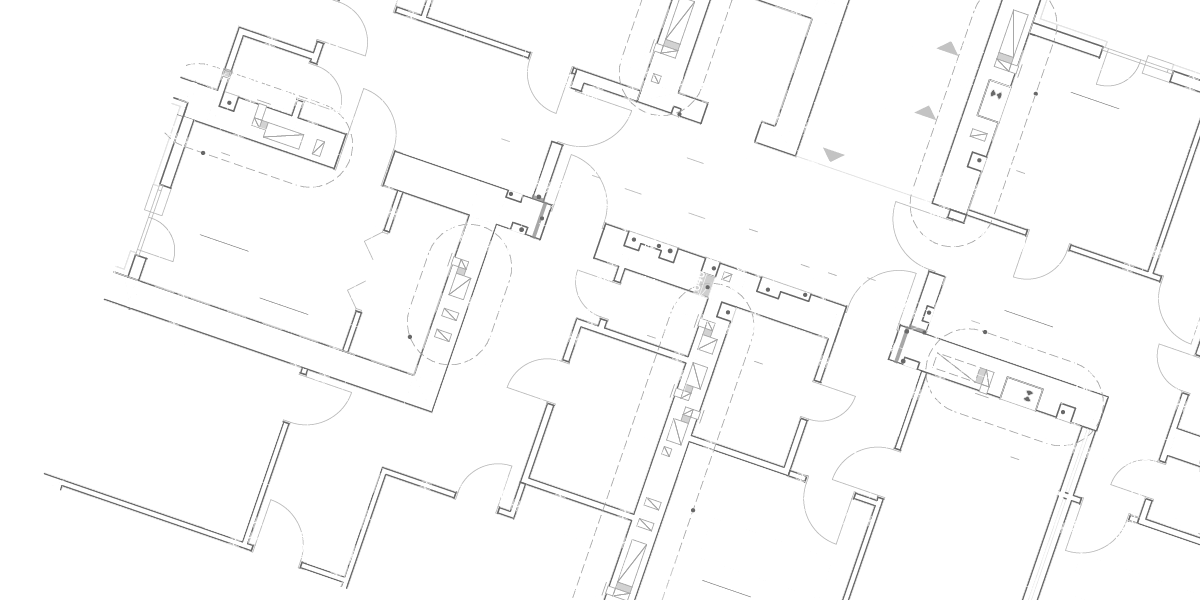

Design and installation

Engineers will need to incorporate the system into your existing or new build, ensuring that all components are designed into the scheme with the required containment and infrastructure in place that the system needs. This includes the power and data cables, trunking, tray work, and conduit. The more complex your backbone and building facility, the more time your engineers will need to factor into the design process, and therefore, the more it will cost. Similarly, the more complex your system is to install and commission, the more time your installation contractors will need to get everything set up onsite.

Testing and maintenance

What a lot of people don’t realise is that the biggest costs associated with an emergency lighting system come from regular maintenance and testing. In Australia and New Zealand, you’re required to test every six months to comply with regulations. The cost of inefficient testing and maintenance can quickly add up, especially if your emergency lighting system is old or relies on manual processes. On the other hand, if you have a modern system with automated testing and simple management, you can save a lot of time and money.

Compliance

Some emergency lighting systems are designed to make compliance easier. This is an important cost consideration because you risk big fines if you’re found to be non-compliant. Or worse - if people come to harm in your building because your emergency lights don’t work, you could face a lawsuit, damage to your reputation, or even imprisonment. Fortunately, compliance is a lot more likely with the right system in place. A computerised testing system automatically keeps a record of testing and maintenance so you can be confident that your team is performing regular tests - and if they’re a contractor, you’ll know you’re getting the service you paid for. Plus, a simpler system with built-in automation makes testing and maintenance quicker and easier, which means you’ll pay less for staff and contractors to check and maintain your equipment.

How to reduce the cost of your emergency lighting

So, how can you save time and money on your emergency lighting system, without compromising on important functions? Here are 10 ways you can save on your next upgrade…

1. Upgrade

It might seem obvious, but the act of upgrading your system can save you time and money, especially when it comes to maintenance and compliance. Older systems built using less efficient technology often require more frequent maintenance. And with manual processes, a physical logbook, and more equipment to maintain, this maintenance also takes a lot longer.

Upgrading your emergency lighting can give you longer lasting battery systems, more efficient lighting, and access to automated testing and management. With better efficiency, the time and cost savings can quickly add up. But don’t just upgrade to any new system - choose a system with the right features so you can maximise savings and longevity.

2. Simplify

As a general rule, the simpler your system, the less time it will take to design, install, commission, and maintain. You could also end up spending less on the initial equipment purchase price.

On the flip side, if you have a complex system, you may need to wire power and data cable to a number of devices, nodes, gateways, controllers, and ancillary devices - and then connect them to a network. This gets more complicated when retrofitting an existing building because you may not have access to the electrical wiring diagrams anymore. Installers and engineers will need to come onsite and figure out where to run cables and how to power the additional devices, which often becomes quite complex.

With a simple dynamic meshed RF system, you plug it in, add the controller, and you’re done. Because the network uses a wireless RF (radio frequency) network to communicate, it’s simple to design and quick to install.

As a side note, this can make a huge difference to onsite project managers, too. Emergency lighting is usually one of the last steps in fitting out a new building or upgrading an existing one. As every PM knows, these projects always run behind. Fortunately, when you choose a simple system, there’s much less chance of something going wrong (that could further add to the project timeline). Your installer comes in and installs the system, then the manufacturer commissions it and does handover - usually within a few days.

Not all new, modern emergency lighting systems are simple, though. In fact, we routinely hear of cases where installers have to spend weeks onsite addressing individual devices just to commission the system. Whereas, best in class systems can often be commissioned remotely once they’re connected to the network.

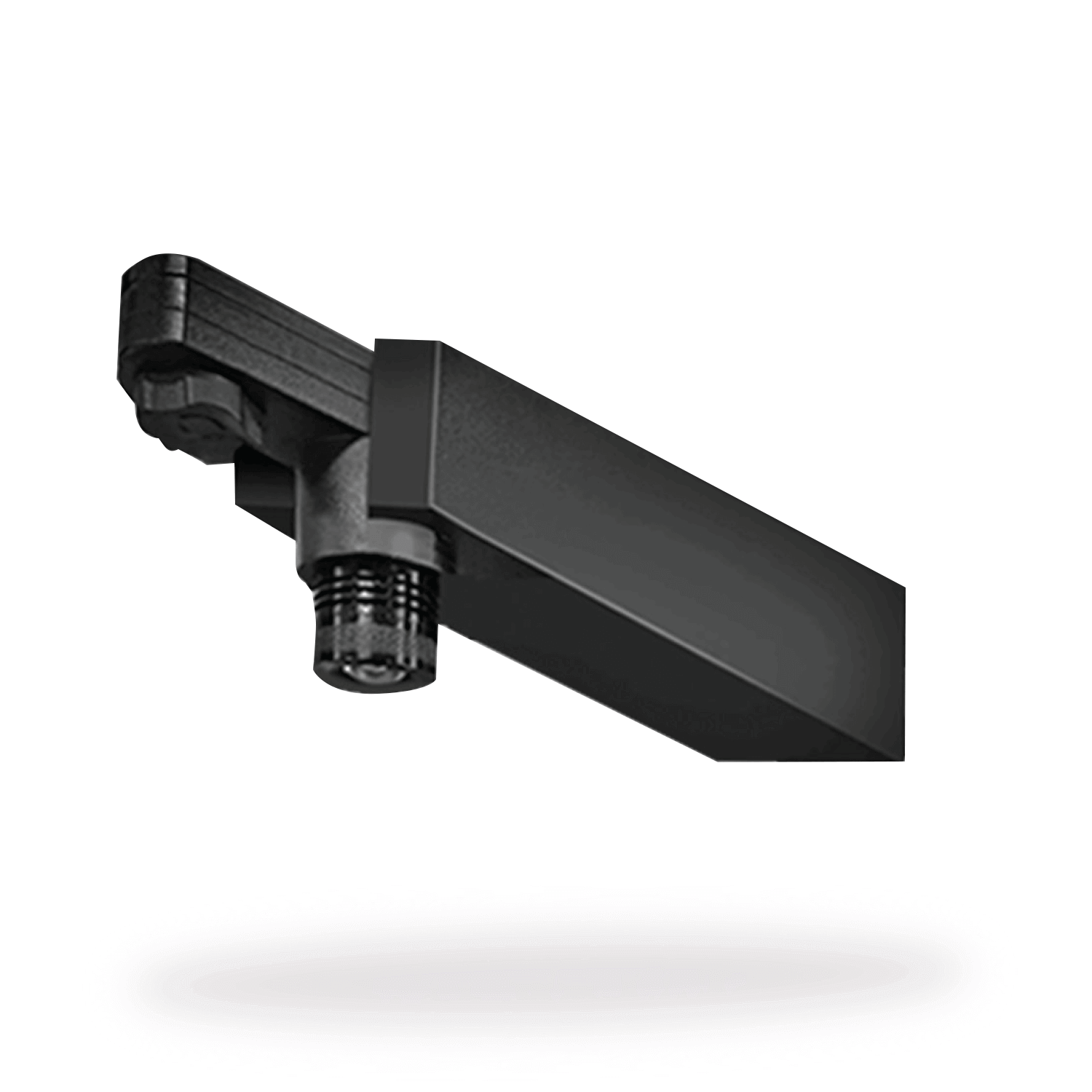

3. Reduce backbone

Backbone refers to all the equipment that’s required to help power and connect your emergency lighting system. This equipment may include:

-

Additional routers

-

Additional controllers

-

Additional repeaters

-

Additional extenders

-

Additional couplers

-

Additional data points

-

Cable between fittings

More equipment means more complexity, labour, and costs associated with installing and maintaining your emergency lighting system. And generally speaking, the less backbone you have, the lower your cost to install, manage, and maintain your system. There’s also less risk that something will go wrong due to someone wiring the wrong device or incorrectly performing a test.

Less backbone = less risk and more savings.

4. Automate network setup

Our preferred emergency lighting system is designed so that the devices automatically build the network. Once plugged in, they use dynamic self-managed (DSM) meshing to self-discover nearby devices and find the most efficient path to send data back to the controller for management and testing. This significantly reduces the time and effort involved in installing your emergency lighting system. It also means that it’s easy to incrementally upgrade your system in stages - simply plug in a new light and it will add itself to the existing network.

5. Automate testing

Most maintenance teams who are in charge of managing large sites often look after 10-30+ buildings at a time. Since they’re in charge of maintaining all the services onsite (heating, air conditioning, and power), emergency lighting is usually a low priority. After all, the building’s occupants aren’t likely to notice if emergency lights fail, but they will notice if the heating is off.

With automated testing, all the testing schedules can be programmed to test at the most convenient time. Instead of two people going around the site for an entire month, your facilities team can check the results of the entire site in just a few minutes. Depending on the number of devices in your emergency lighting system, automated testing could save your maintenance team anywhere from 2 hours per week to the equivalent of two full-time roles. It’s the best way to ensure compliance without recruiting more staff for your facilities team and could save you thousands per year.

6. Increase transparency

Many older systems rely on manual testing and physical logbooks to record compliance. This isn’t just inefficient, but it means you have to trust that the recorded tests and maintenance work has been done. We’ve heard stories about service sheets being filled out and sent back, saying that everything’s okay. Then upon further investigation, management found that the sheets were filled out incorrectly, with 20-30% failure across the luminaires.

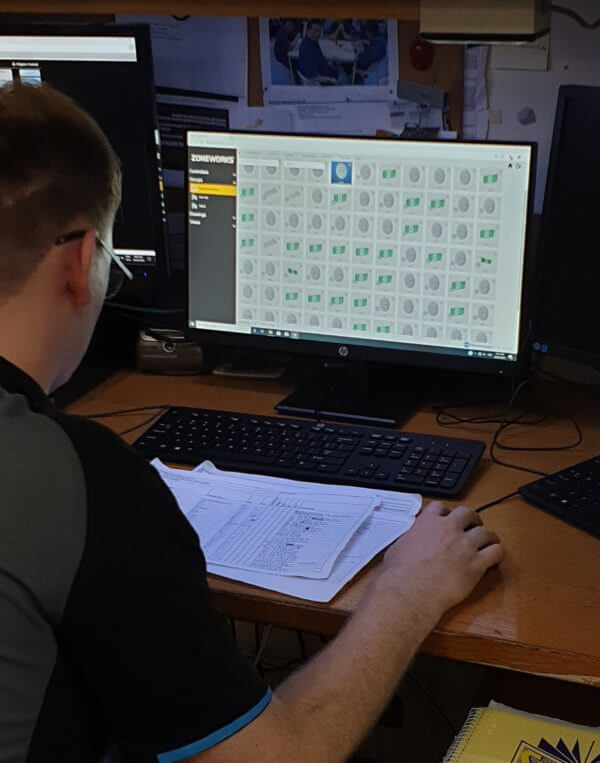

A computerised system prevents this situation by increasing transparency. It keeps a digital log of all the automated test results, shows the live status of every emergency luminaire, and has an integrated maintenance log to show what maintenance activities have been done. It means that when you’re audited, you’ll always have test logs and maintenance reports ready to go. You can also be confident that the data is accurate and that you’re not getting ripped off by contractors.

7. Centralise management

One of the other benefits of a computerised system is the ability to centralise management. For example, some businesses might have multiple campuses or 100-200 retail sites across the country. An advanced emergency lighting system will allow you to connect the controllers to a virtual server and manage, test, and control all your emergency lighting from one place. You could engage a subcontractor to manage the system from a central point hundreds of miles away. In fact, we’ve been able to commission a system in London (using centralised servers in Melbourne) from an office in Leeds. It is a truly global approach with the right system.

This allows you to save money by minimising the amount of travel needed between sites and reducing the number of subcontractors you need to maintain your systems.

8. Choose closed source

Some manufacturers build their systems to operate on open source protocols like DALI (Digital Addressable Lighting Interface). Open source is associated with being free, flexible, and easy to control, but is it really ideal for a critical device like emergency lighting? We’ve found that if there’s a problem in the system, it can be hard for the end user to determine which part or manufacturer is at fault. If you’re going down this track, make sure you know who will take responsibility for the entire system, because it can be extremely challenging and costly to get problems fixed.

On the other hand, a closed source system (like the one we use) is lower risk for customers. The provider is responsible for updating, testing, and releasing changes, and ensuring the software works with the specific hardware it’s designed for. If there are any issues, queries, or support required, the manufacturer will take responsibility for them and provide direct support.

9. Optimise for emergency lighting applications

DALI test systems are quite common - but that doesn’t mean it’s the best option. DALI is primarily designed to control general lighting. These luminaires contain a DALI driver which allows the system to control the output of the luminaire to save energy. Some engineers incorporate emergency lighting management and testing into the DALI system because they believe it will save money and simplify management, but this can actually become more complex and expensive to install, commission, and maintain (compared to a purpose-built system that’s optimised for emergency lighting).

Most people believe that if you have a DALI control system, the DALI test system is a free add-on, but the costs can quickly add up. DALI allows up to 64 addresses to connect to a gateway. Some limit this to around 50 or so to allow for future expansion. Every mains luminaire converted to DALI test will take two addresses, resulting in additional gateways and wiring. You also have to wire data cable to all exit sign luminaires and all emergency luminaires which are back of house or may not be linked to the DALI system. So, the hardware costs can quickly add up, along with the costs of converting the fittings to emergency.

Plus, it’s best practice to have a separate system for emergency lighting systems. Emergency luminaires are part of a life safety system, so any fault or issue reported should be clearly visible and easy to spot. If emergency luminaires make up just 10% of a general lighting system, you risk faults getting lost in the visual noise of a system that’s designed for energy saving and aesthetics.

10. Prioritise support and training

There are good and bad emergency lighting systems on the market, but most of those that are perceived to be bad actually aren’t. It’s just that the end users haven’t been properly trained in how to use them. A system is only as good as how you use it. If your team doesn't know how to use the system correctly, they could make costly mistakes and even cause it to stop working. That’s why it’s critical to ensure that your emergency lighting system comes with good support and training.

Here at Clevertronics, support and training are a huge priority for us. We offer LTS (Lifetime Technical Support) at no cost for the lifetime of the product, including software updates and training. That means we’ll be there to provide onsite and offsite training to new and existing staff, and our customers always have a point of contact who can help them.

If you need to install new emergency lighting, reconfigure the system, or meet new standards, we’re available to help. Not only do our customers save money because they’re not paying for ongoing support and technicians, but they can be confident their staff are trained so they get maximum value out of their investment.

Ready to find out how we can help save you money?

Want to know more about how you can cut costs on your emergency lighting (without compromising on compliance or function)? We’re here to help so contact us today and find out how the Clevertronics team can assist with your next project.