Introducing the latest Major Upgrade

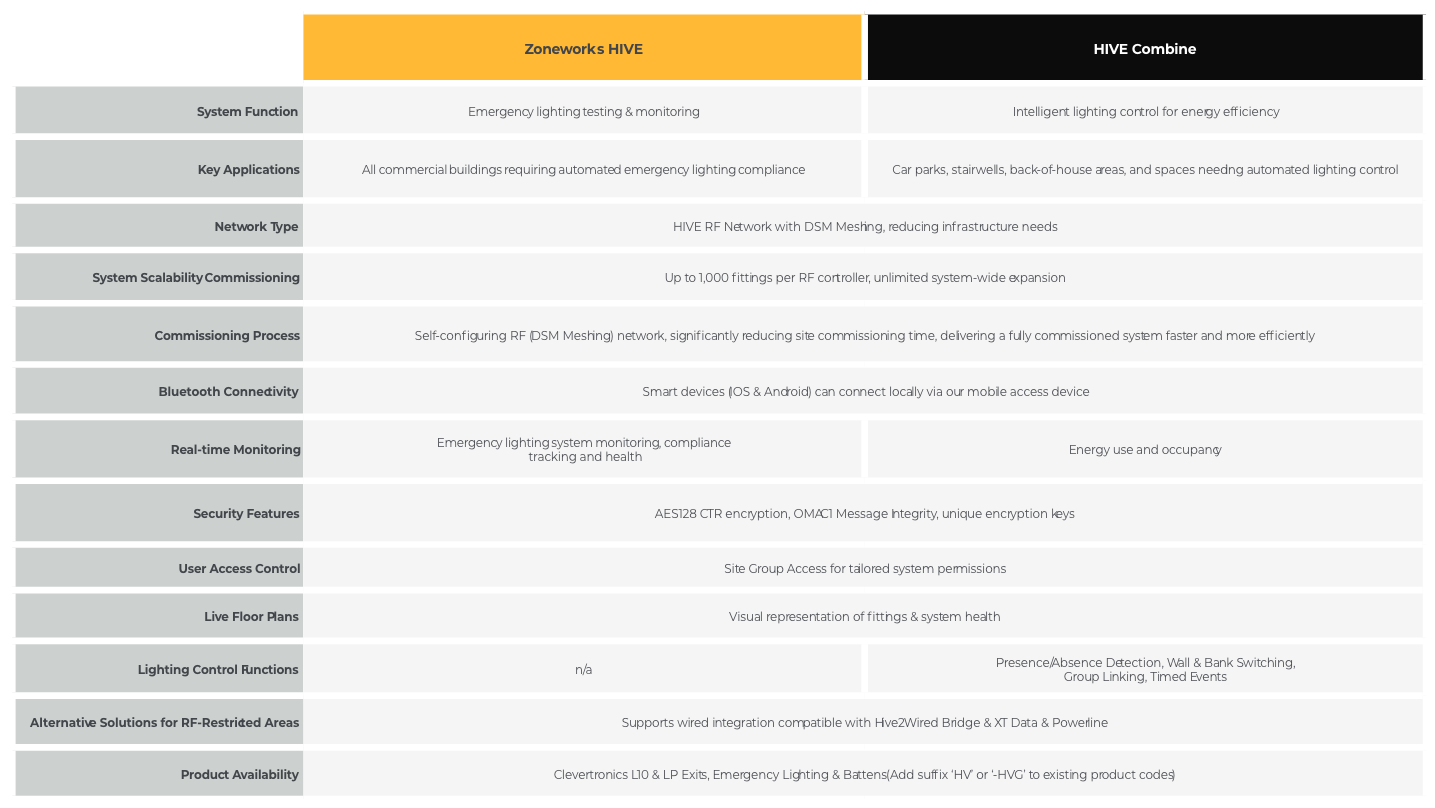

Zoneworks HIVE Combine is the solution that provides the required functionality and reporting in car parks, stairwells, and back-of-house areas. Best of all, it now comes standard with Zoneworks HIVE at no extra cost.

Until now, those looking to meet energy compliance, functionality, and reporting requirements for car parks and stairwells had to choose between:

- Basic on/off sensors without any additional functionality or reporting

- A complex lighting control system requiring additional infrastructure, installation, and ongoing maintenance expenses.

In many cases, due to these factors, a system approach is never taken due to the complexity and costs, leaving these key areas with a lack of adequate functionality and reporting.

What is HIVE Combine?

HIVE Combine is a lighting management system that utilises the existing Zoneworks HIVE system to provide energy consumption, occupancy sensing and system health through an easy-to-use and data-rich dashboard.

This allows for the optimal configuration of lighting outcomes in your car parks, stairwells, and back-of-house areas to save you money whilst providing a safer and desired outcome for users.

The easy-to-use Zoneworks HIVE Combine interface provides all the required functionality settings to configure the lighting outcomes across the Car Park, Stairwells, Back of House and Plant Room areas.

Functionality includes

Unmatched Simplicity

The Zoneworks Emergency Lighting platform has continuously evolved and is a trusted solution that has been successfully installed in over 4,000 facilities over the past 15 years.

The update to Zoneworks HIVE was a game-changer as it reduced the backbone to one single controller for 1,000 fittings and introduced dynamic self-managed meshing to make design, installation, commissioning and management simpler than ever before.

Adding lighting control to Zoneworks HIVE for areas such as car parks, stairwells, plant rooms, and back-of-house provides a seamless compliance approach. One system and no additional cost.

Hive Combine enhances Zoneworks HIVE by adding intelligent lighting control, optimizing energy efficiency, and streamlining compliance—without additional infrastructure or complexity.

Designers

Simpler...

Control, No Extra Complexity

- Seamlessly integrates with Zoneworks HIVE, eliminating the need for separate lighting control systems.

- Adds presence detection, absence detection, and group linking, simplifying design.

Contractors

Faster...

Installation, No Extra Hardware

- Utilizes the existing HIVE network, using the same controllers as the emergency lighting, DSM meshing, and simple commissioning.

Facilities Managers

Easier...

Energy Management & Compliance

- Real-time energy monitoring optimises efficiency and cost savings.

- Occupancy-based control enhances safety and reduces waste.

- Centralises emergency and general lighting systems.

Dashboards for Zoneworks & HIVE Combine

Real time visibility for emergency lighting compliance and energy performance

The Zoneworks HIVE & HIVE Combine Dashboards deliver powerful, real‑time insights that help facility managers, electrical contractors and building owners stay on top of emergency lighting compliance, system health and energy efficiency. Designed to simplify complex data, the dashboards provide instant visibility across every building, zone and lighting group - improving safety, reducing maintenance costs and supporting smarter decision‑making.

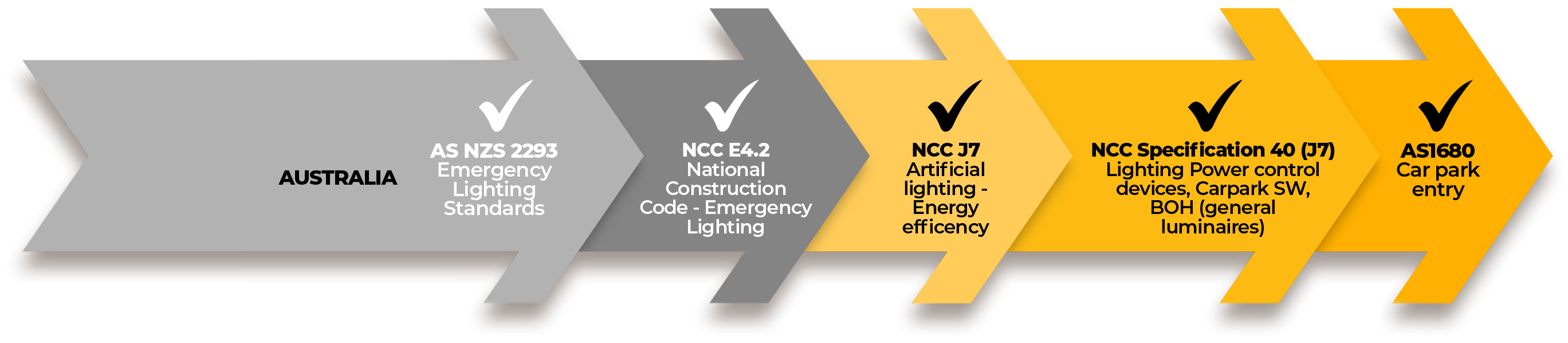

Zoneworks HIVE now combines emergency lighting and lighting management regulations to simplify compliance

How does HIVE Combine solve the problem?

The HIVE Combine solution

The Zoneworks Emergency Lighting platform has continuously evolved and is a trusted solution that has been successfully installed in over 4,000 facilities over the past 15 years.

The update to Zoneworks HIVE was a game-changer as it reduced the backbone to one single controller for 1,000 fittings and introduced dynamic self-managed meshing to make design, installation, commissioning and management simpler than ever before.

Adding lighting control to Zoneworks HIVE for areas such as car parks, stairwells, plant rooms, and back-of-house provides a seamless compliance approach. One system and no additional cost.

Adding lighting control to Zoneworks HIVE for areas such as car parks, stairwells, plant rooms, and back-of-house provides a seamless compliance and energy management approach.

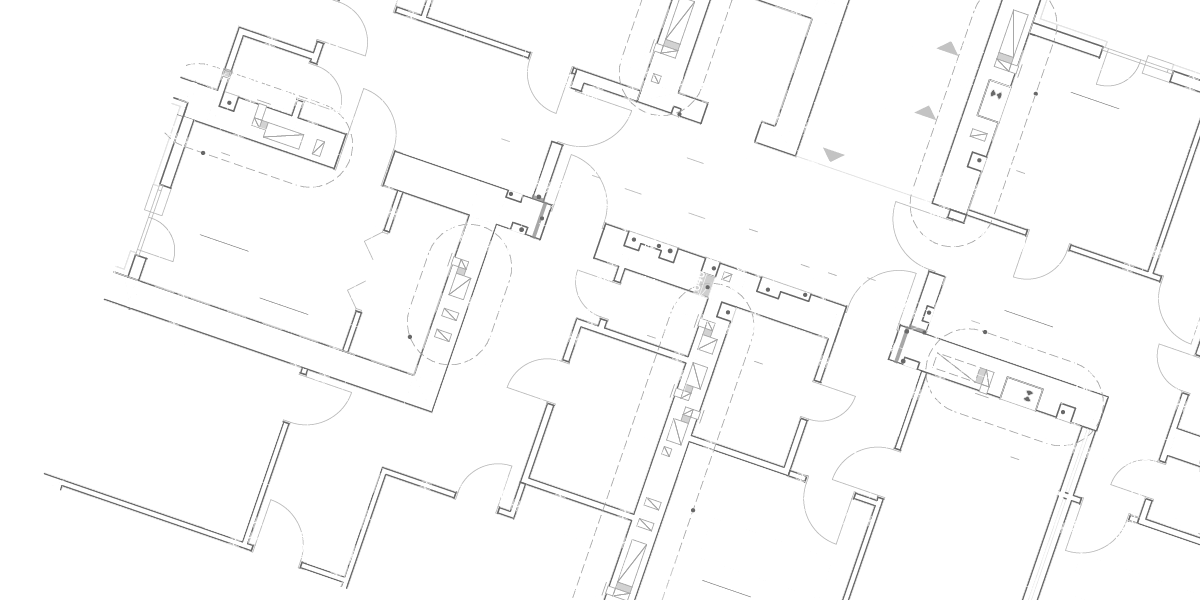

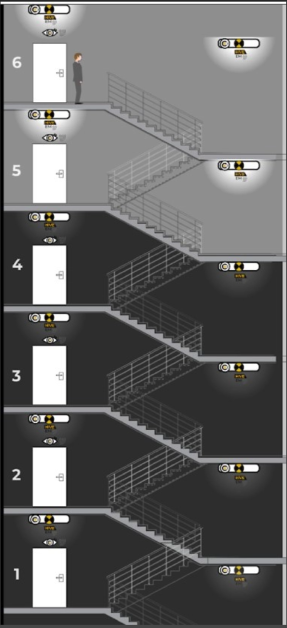

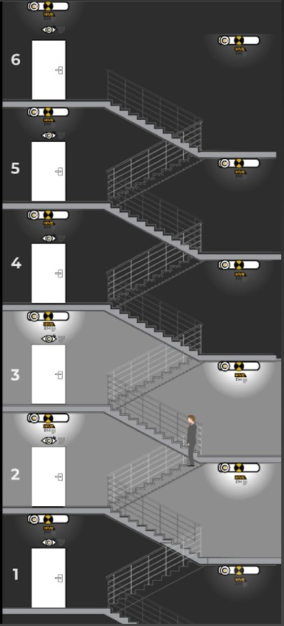

Stairwell Application

Lighting Management in a stairwell is achieved very easily using HIVE Combine. The following scenario outlines an example of group control.

Group Control Example

All luminaires in this example are emergency HIVE Combine enabled, using stand-alone motion sensors or sensors built into the luminaire at the entry door. Presence on entry turns the landing and half-landing luminaires on and simultaneously turns on the luminaires at the level above and below.

As the occupant moves down the stairs, the level below is turned on, and the upper levels dim and turn off as they time out. This type of grouping can be configured in countless ways depending on the requirements of the building. HIVE Combine makes this control easy and is more effective than basic sensors in every fitting.

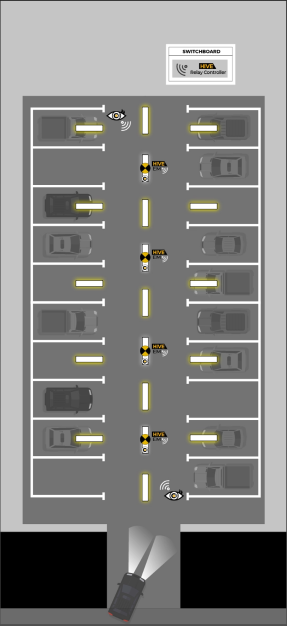

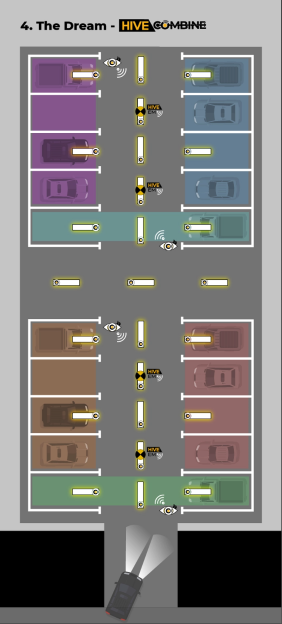

Car Park Application

The above scenarios outline two solutions which are described as bank switching control and individual control.

Bank Switching Example

Involves stand-alone or integral HIVE sensors to activate banks of luminaires upon presence detection on entry. Every second driveway luminaire is a HIVE Combine emergency luminaire with integrated sensor to also detect presence and dim to a set level after timing elapses.

Individual Control Example

All luminaires and sensors are HIVE Combine enabled. The luminaires can be set up in groups as required to be triggered by presence detection and/or timed events. Energy and luminaire health information available for every individual luminaire in addition to dashboard views.

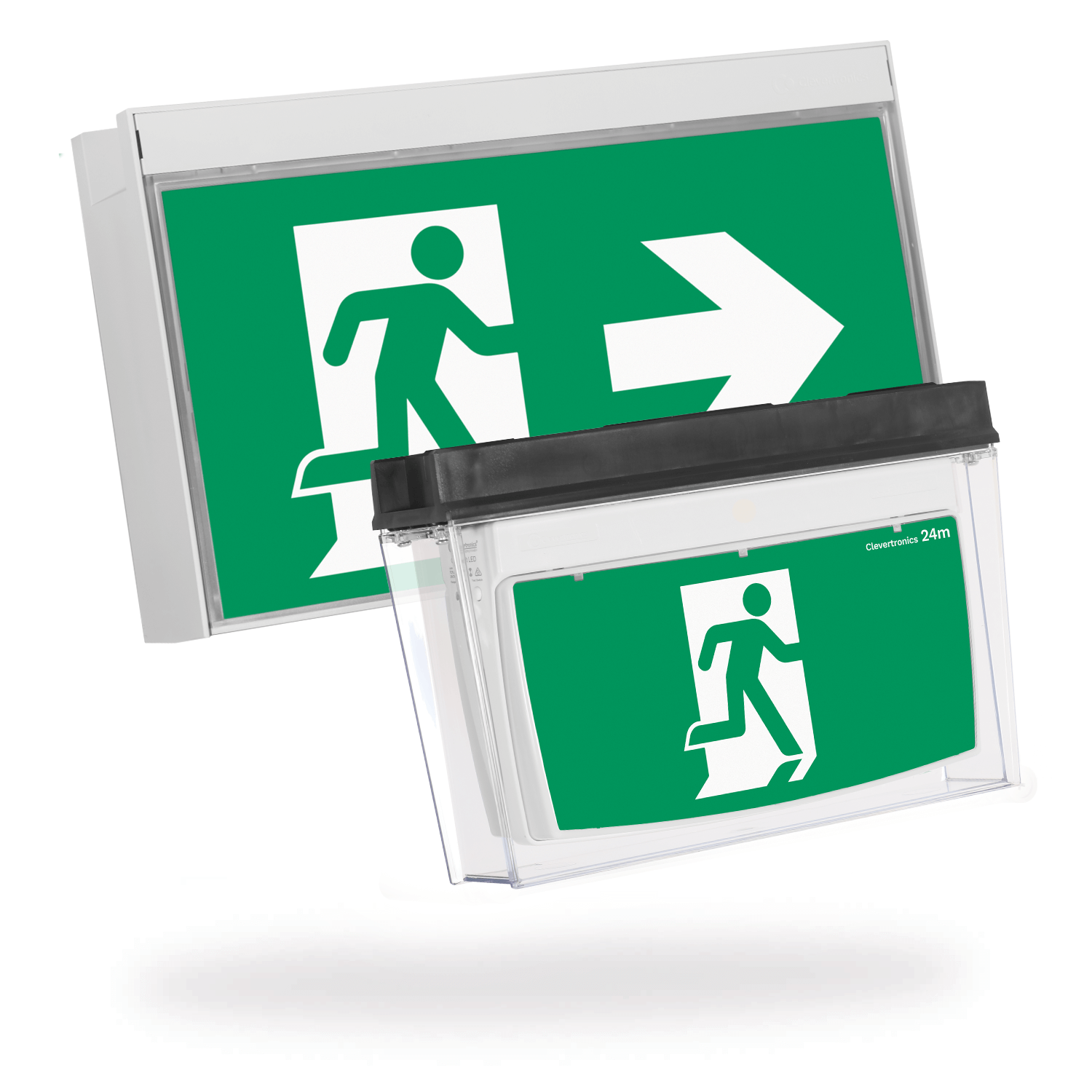

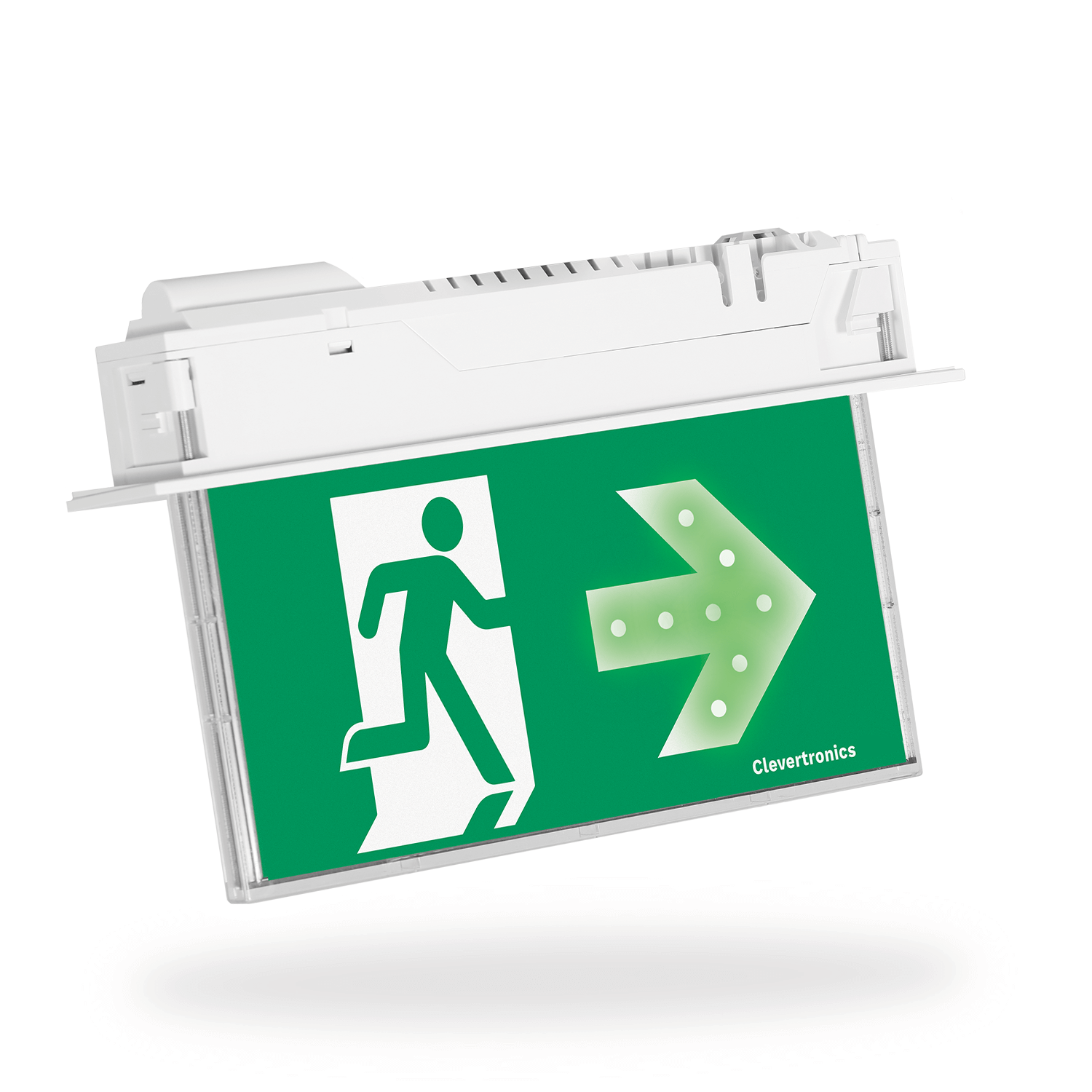

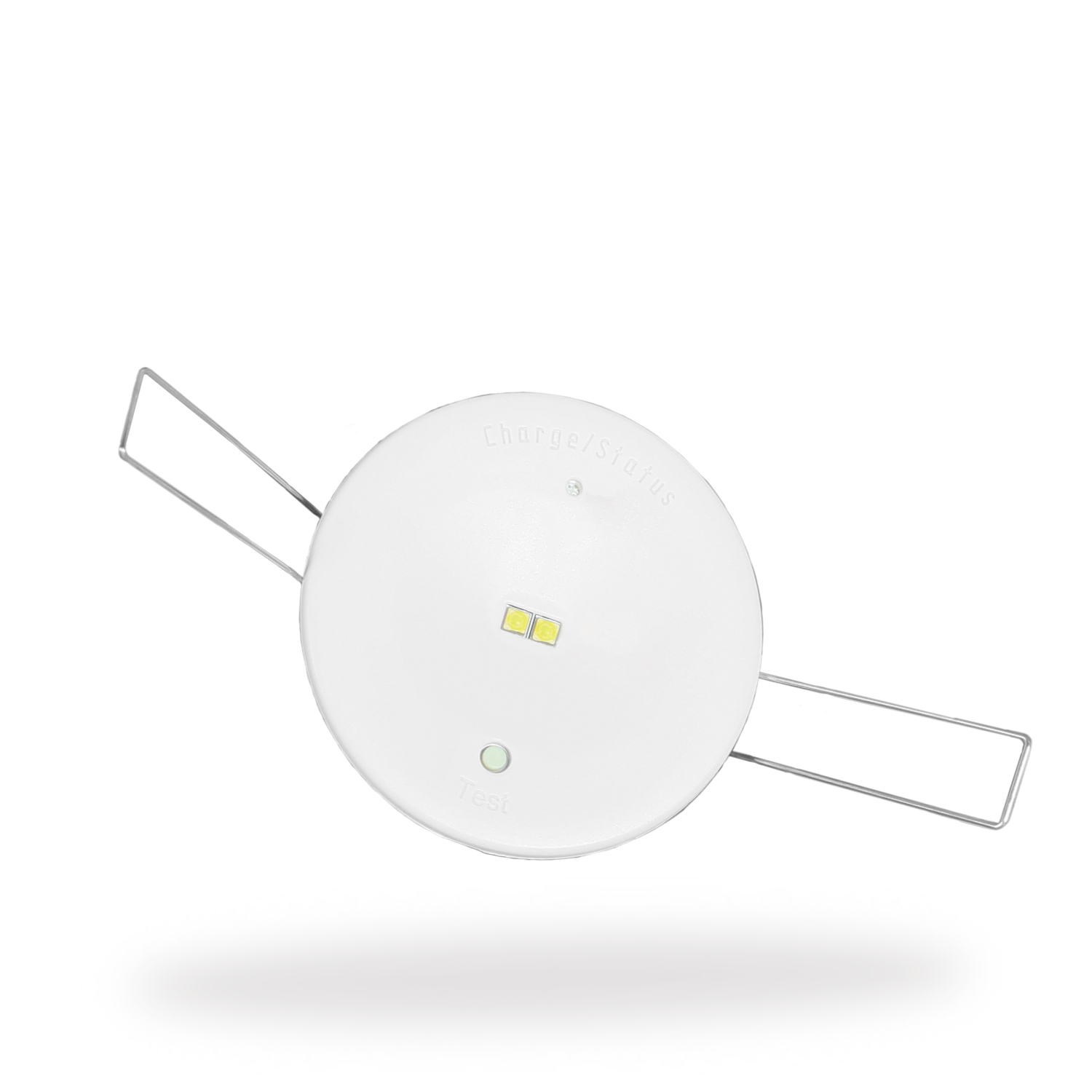

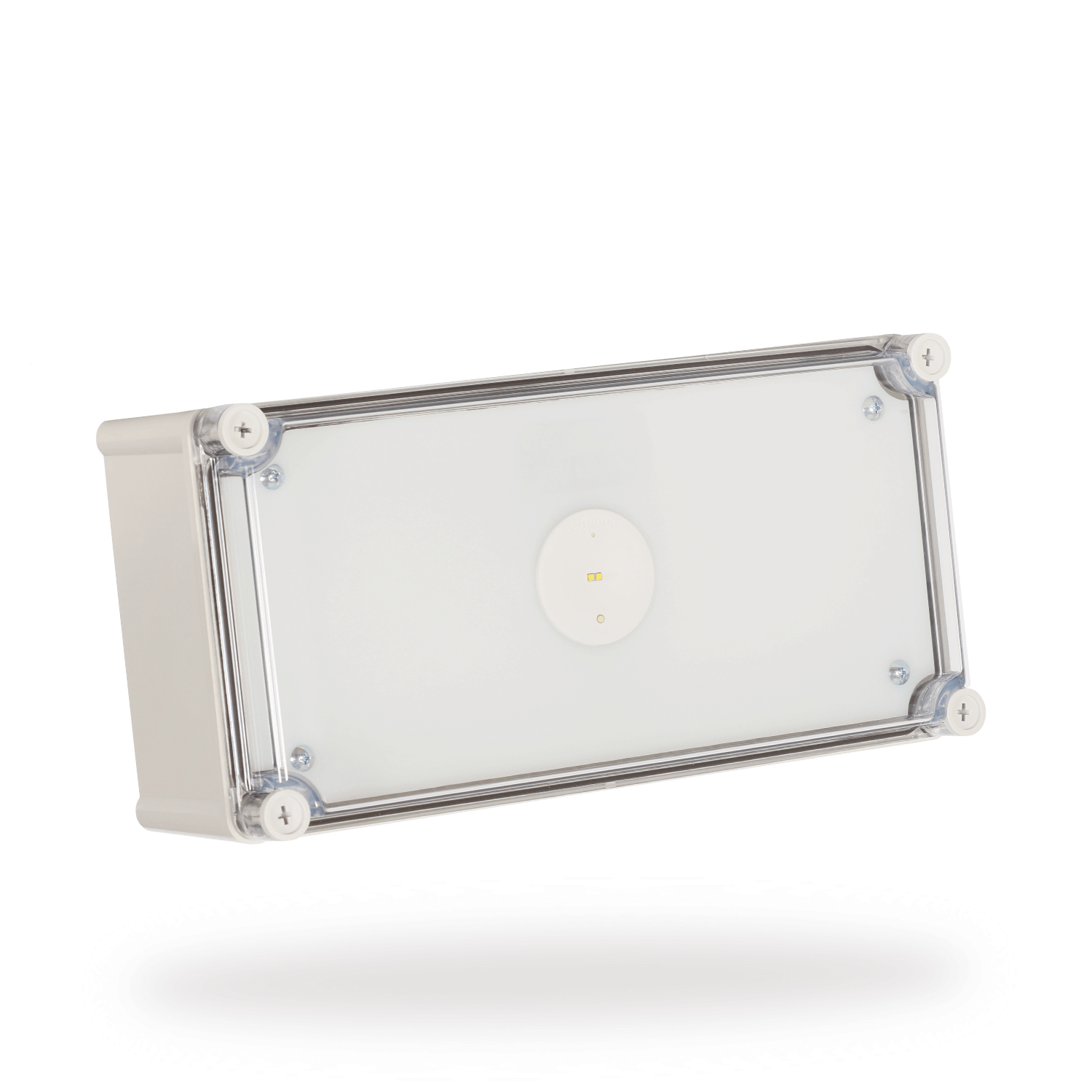

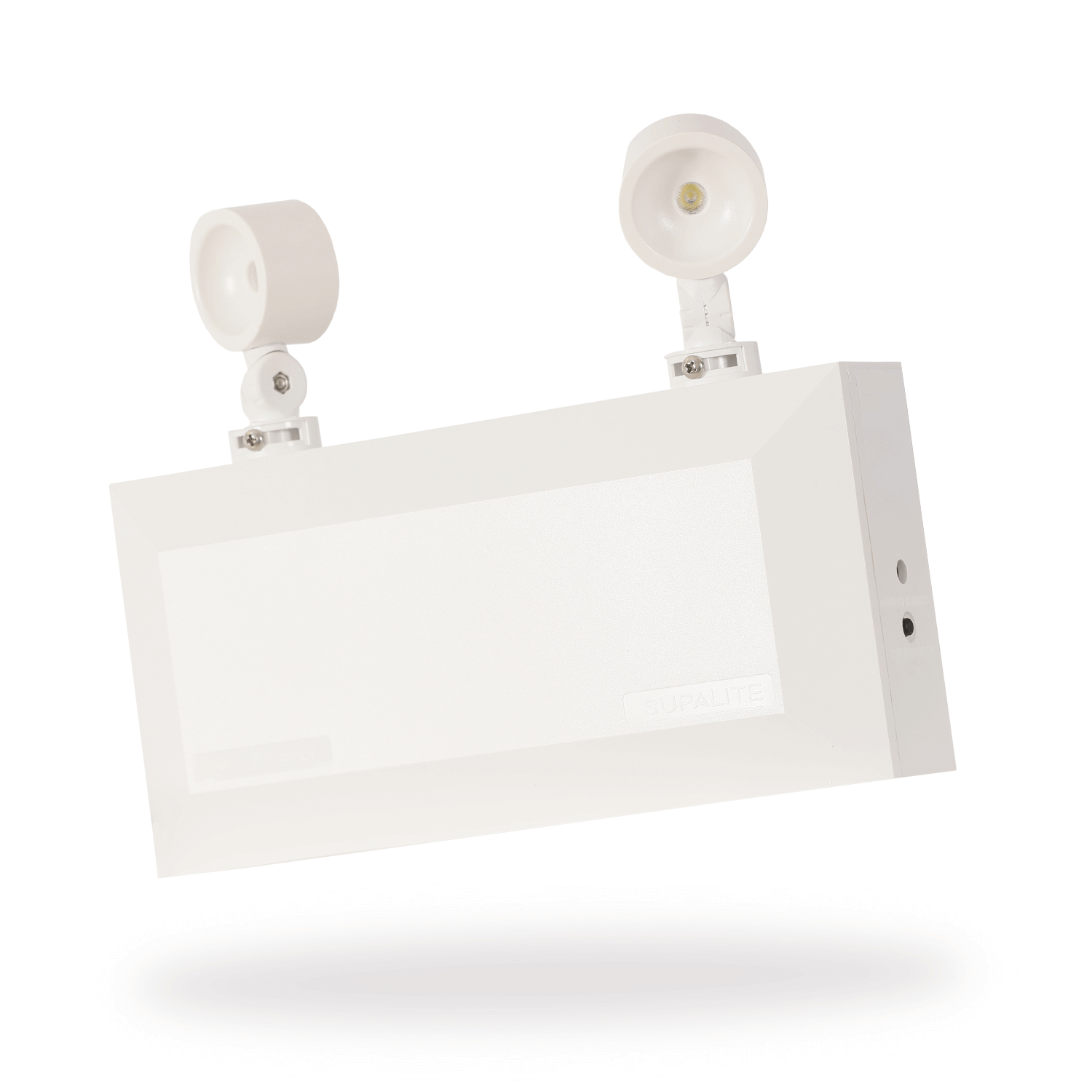

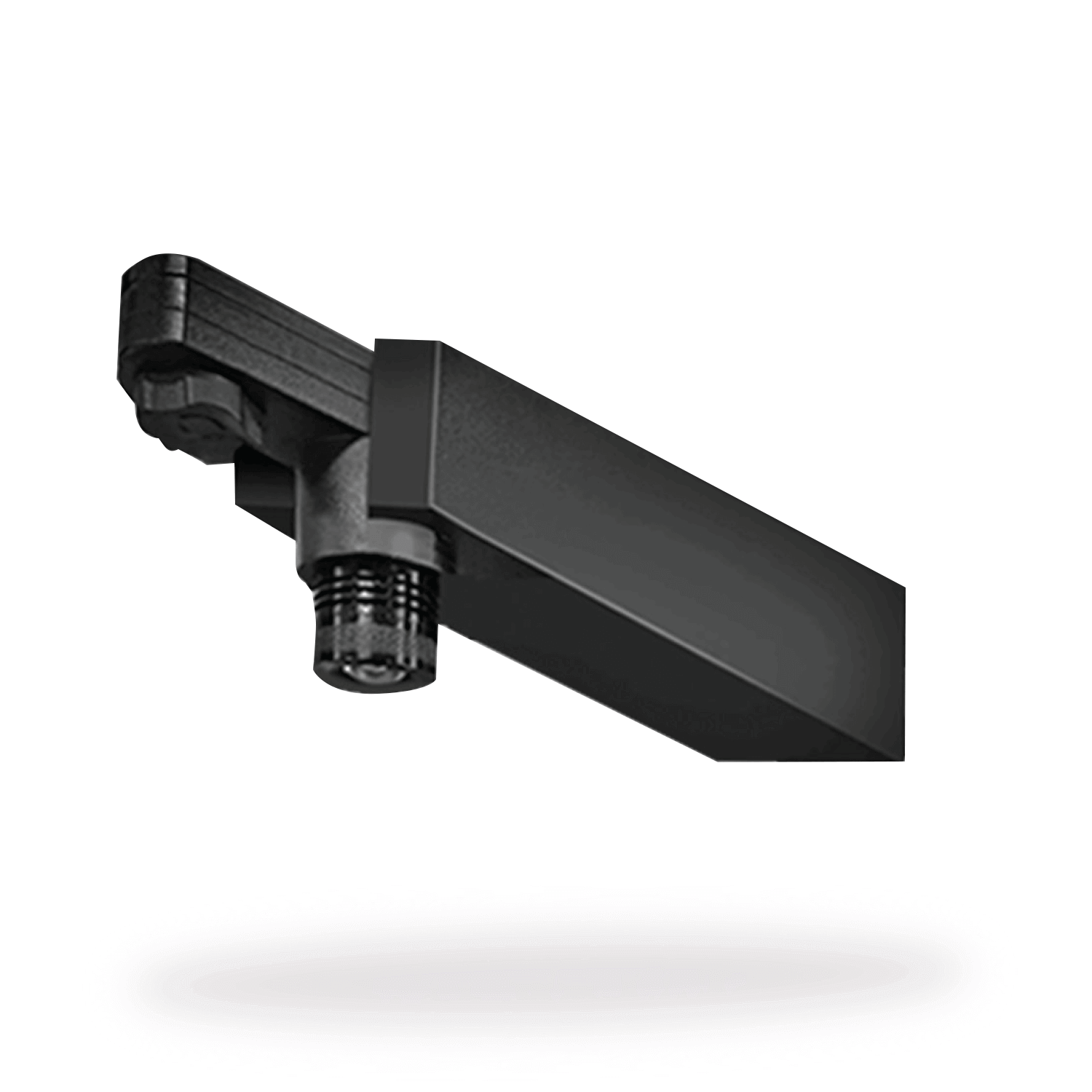

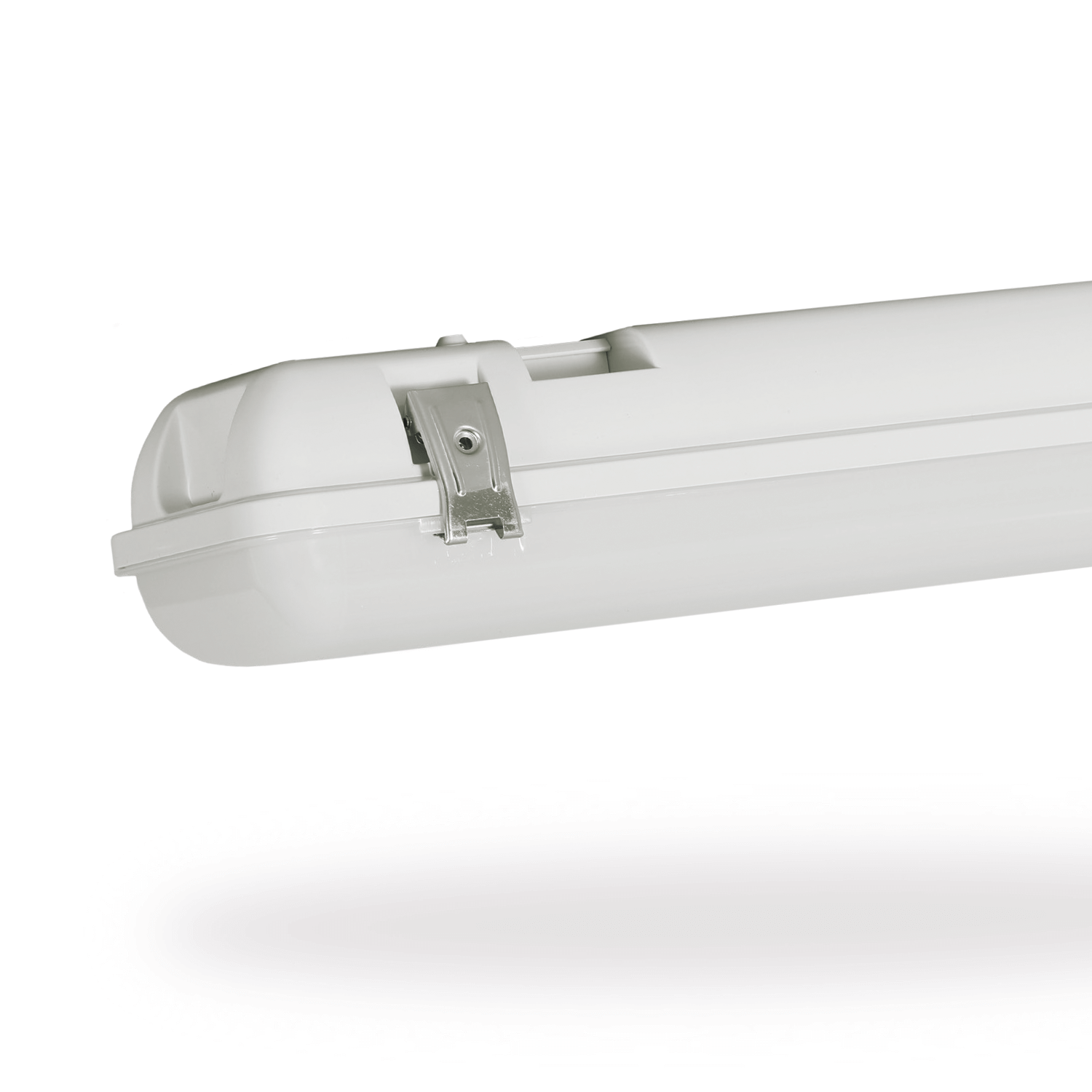

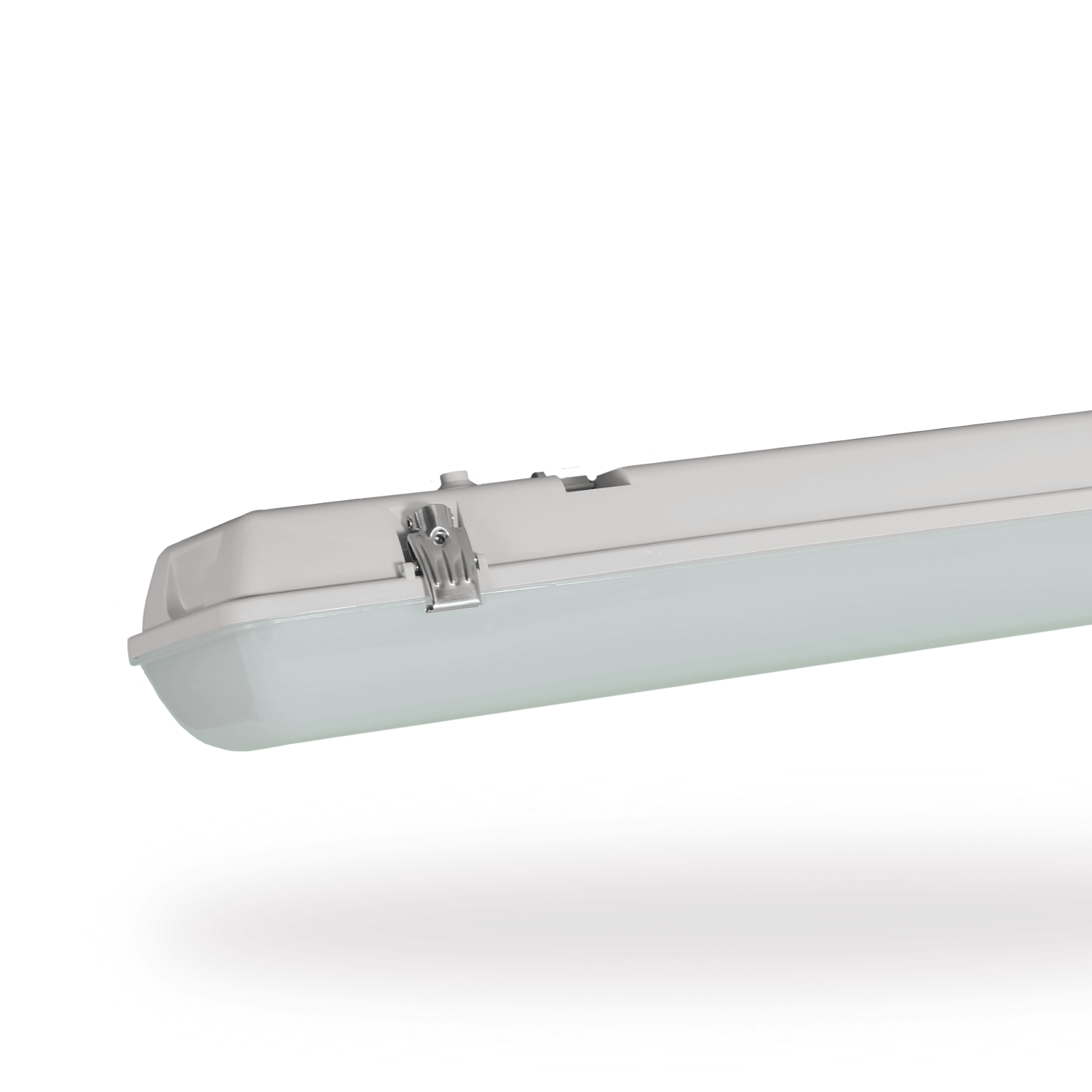

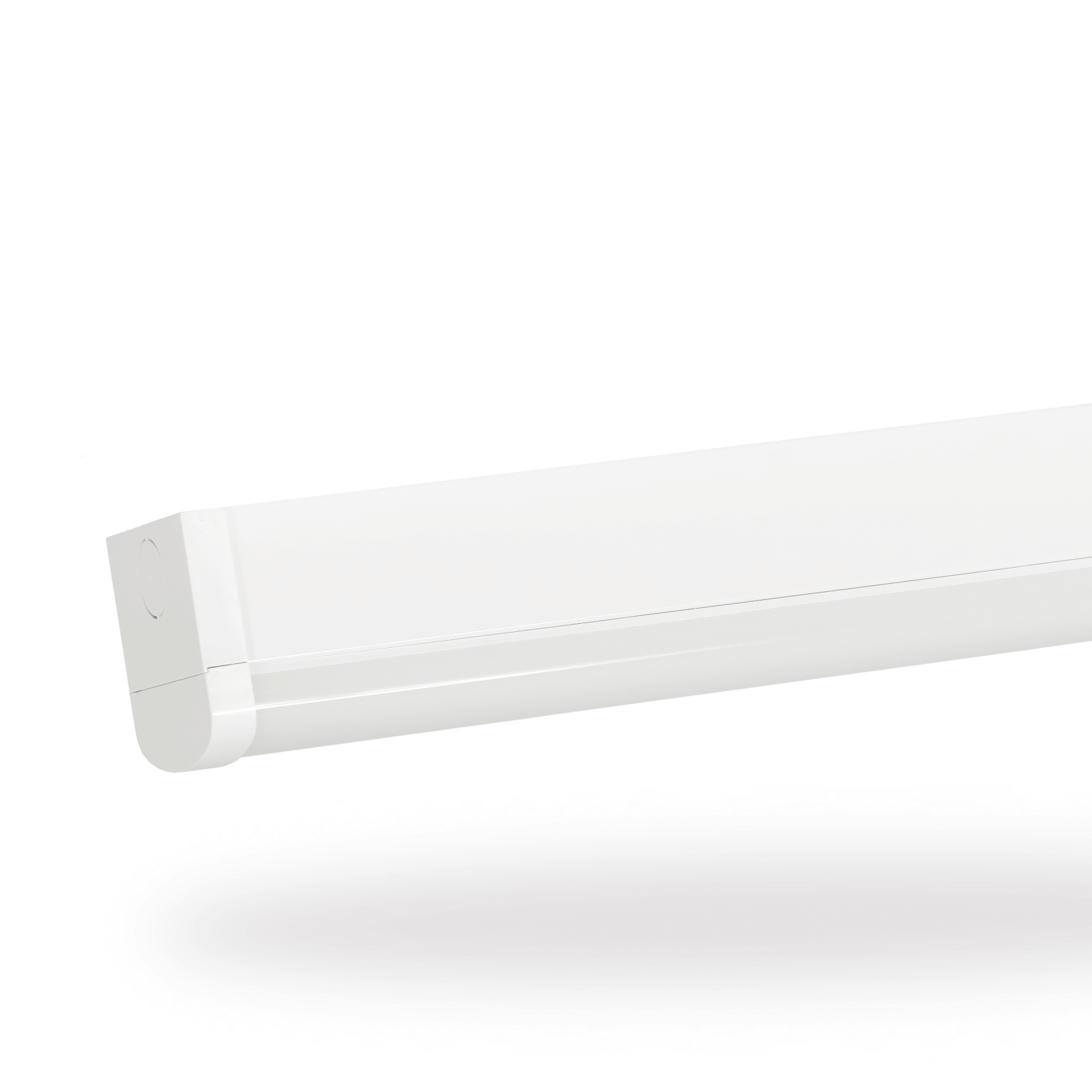

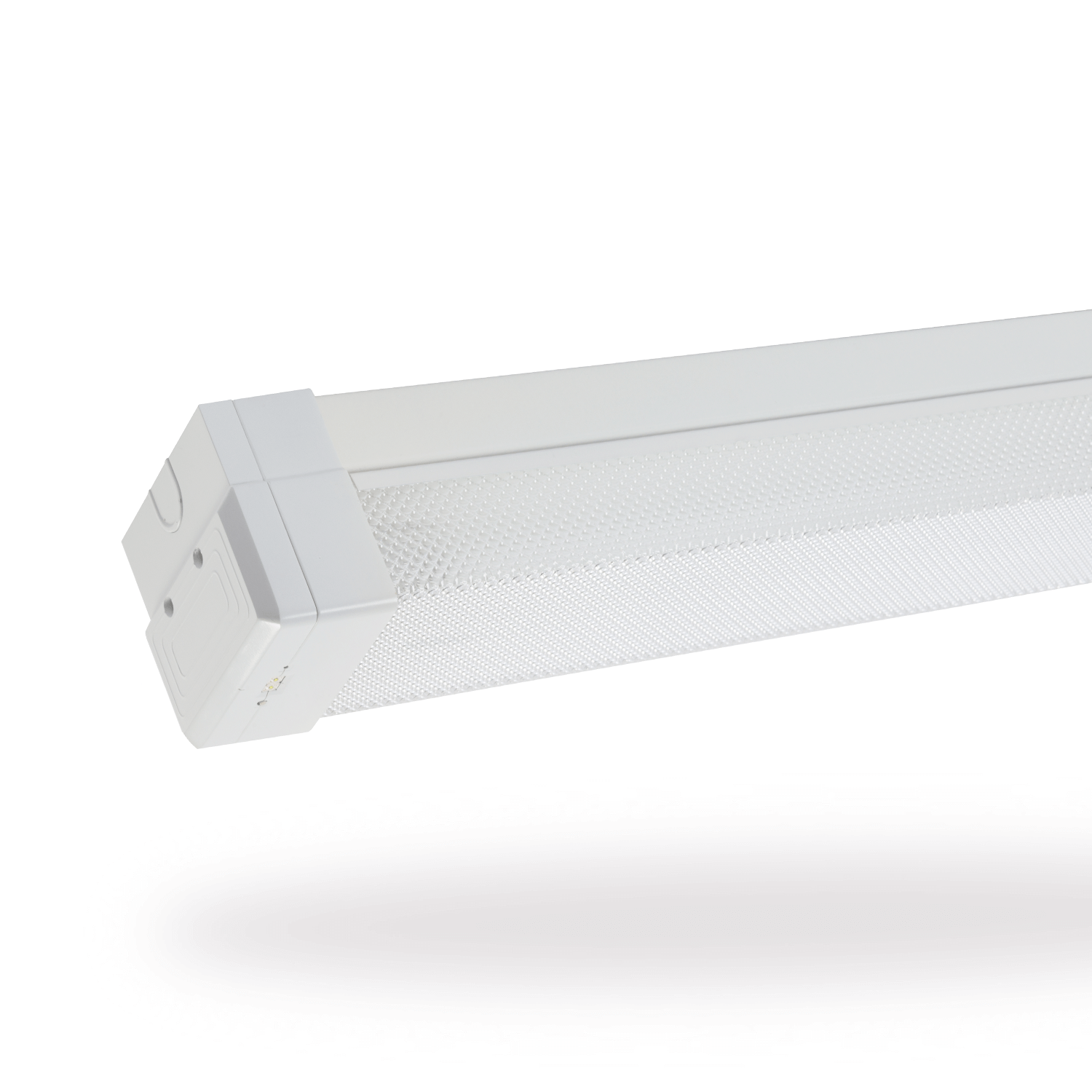

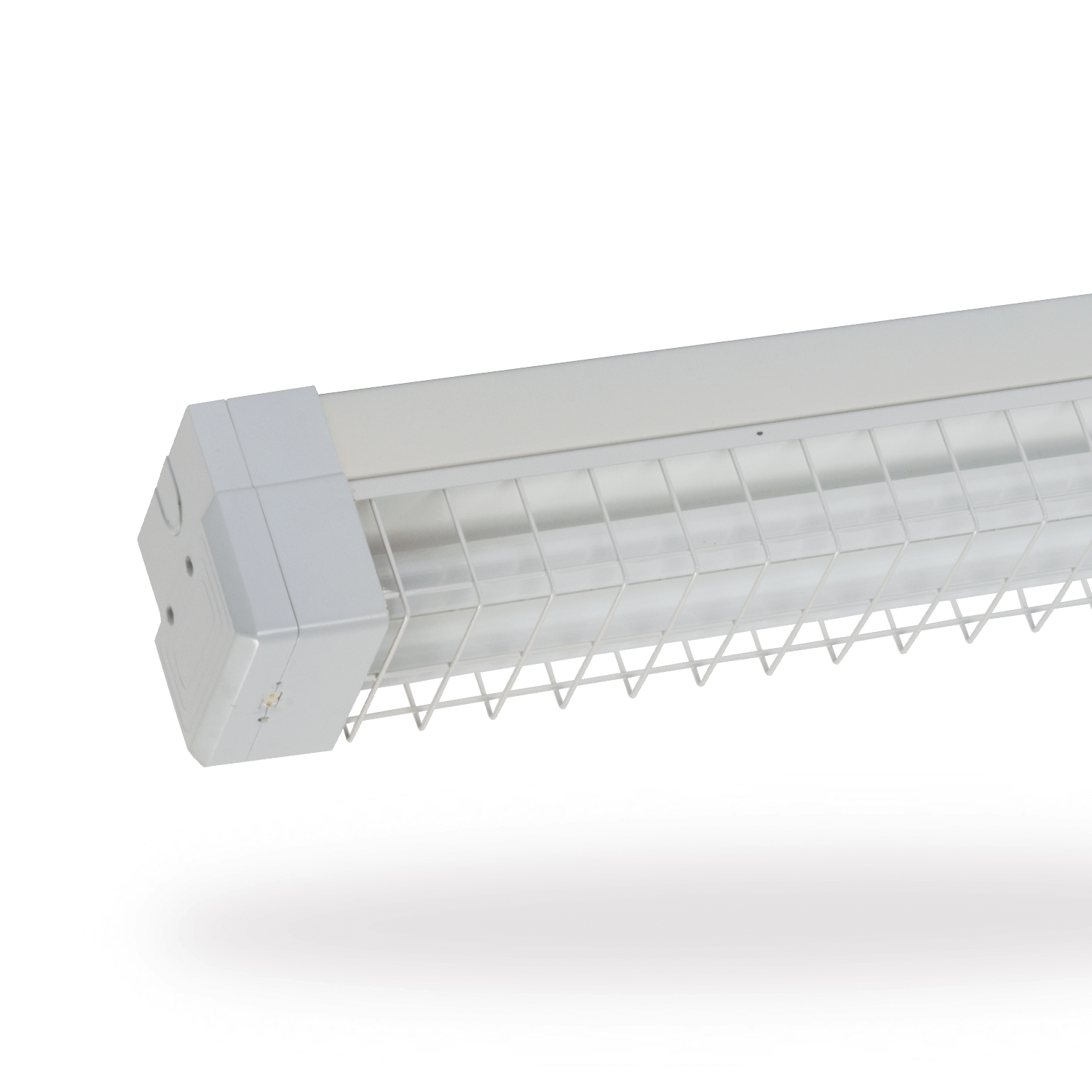

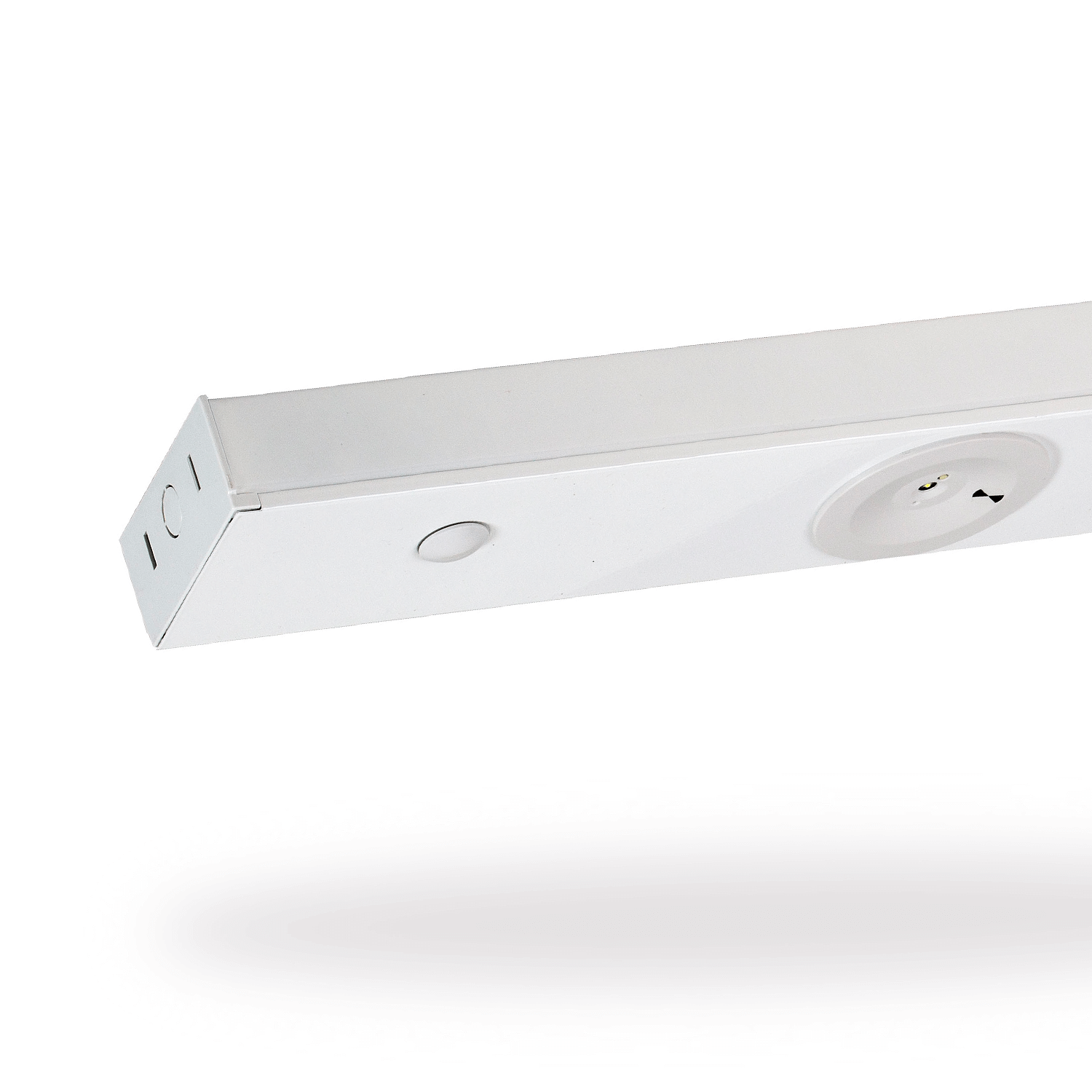

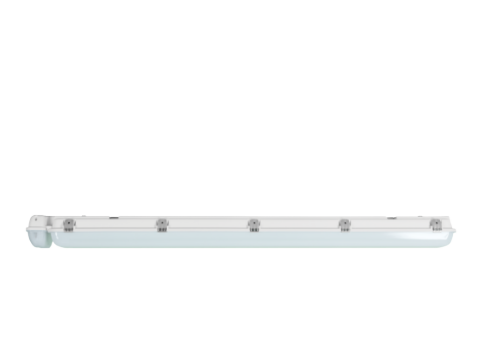

System Products

System Peripherals

Contact Clevertronics for lighting design & further information

Your Partner in Compliance & Lighting Control

With the Zoneworks HIVE platform, Clevertronics also includes ongoing support through our complimentary Lifetime Technical Support (LTS) program. This service is designed to help the building owner & maintenance contractor manage the on-going health for the life of the system.

Emergency lighting is regarded as a life-saving device, and therefore, it should always in working order. Compliance with the standard can be costly, especially if the products and operating systems regularly fail.

Many emergency lighting companies finish their involvement on your project once the product has been supplied. However, at Clevertronics we know that on-going support is important to contractors and building owners.

To learn more about Lifetime Technical Support (LTS) Click Here

Technical Overview

Downloads

| Files | |||

|---|---|---|---|

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

||

|

|

Frequently Asked Questions

-

Are the HIVE fittings compatible with structured cabling installations?

Yes, as long as the fittings are powered up they communicate messages via RF without further reliance on the cabling infrastructure.

-

Can older/existing ZW sites be upgraded to ZW HIVE?

Yes, older sites can be upgraded and it would be recommended to do this as a gradual upgrade as the fittings require replacement. An upgrade will require the installation of an HIVE controller.

-

Will HIVE fittings have a visible antenna?

No is the general rule but metal fittings like our surface mount cylinder will have a visible external antenna.

-

What happens if I have 1,050 fittings on a site – is the 1,000 fittings per controller absolute?

Yes, this maximum number of fittings per controller is absolute. For 1,050 fittings you will need a second controller.

-

Is CleverEvac compatible with HIVE?

Yes, HIVE actually makes it simpler and easier to monitor CleverEvac fittings.

-

Does the HIVE system come with the advantage lifetime support program?

Absolutely, After-sales support with the ALS program continues as usual with HIVE sites.

-

How do I design an HIVE system?

An HIVE system is very simple and fast to design. Simply allow 1 HIVE controller to be installed to manage each 1000 emergency lights and exit signs. In a typical building scenario install the controller in the core area next to the facility managers office, provide it with an ethernet port for network access then add the emergency fittings onto the lighting circuits. No networking cables or additional aerials required! Contact your local Clevertronics office for free expert design assistance.

-

Are there any issues with interference between the HIVE RF signal and other RF frequencies in a building environment?

With HIVE DSM Meshing there is no single point of failure because all the devices are homogenous and can forward data as required. It is self-healing and reacts to changing physical or radio environments automatically. The HIVE Mesh is robust against interference. There can be several different wireless systems in the same area. Devices within the HIVEMesh locally choose the best channels to operate in whilst minimizing interference to other radio systems. In case a message is lost it will automatically be re-sent until it’s receipt is verified.

-

What is a MAD Device and how is it used?

A “MAD” or Mobile Access Device is a mobile commissioning and diagnostic tool that can be used to connect with individual or groups of fittings locally on a site. A MAD is a handheld unit the size of a mobile phone that can connect via Bluetooth to a mobile device (Phone or Tablet) and to fittings via an RF signal. Though not needed to commission a site it can be especially helpful for maintenance contractors and facility managers to perform function tests at individual fittings and check the live status of fittings locally after performing maintenance.

-

Can you connect a phone via Bluetooth to each fitting?

Yes, A Clevertronics MAD device can be used as an interface between a mobile device (Phone/Tablet) and individual fittings on a site. Please read the FAQ “What is a MAD device and how is it used. -

Is the MAD (mobile access device) locked to a site or can a maintenance contractor use across multiple sites?

The MAD can be used across multiple sites, however, users will need the local XT Hive network key to access a specific network. In that way, we prevent unauthorised access to any given network.

-

How can you tell that the fittings are communicating via RF?

Check the status LED on each fitting

-2 amber flashes for uncommissioned but no controller found

-1 amber flash for uncommissioned and controller found -

How far can HIVE fittings communicate?

The minimum expected line-of-site coverage is 200m and the 2.4GHz signal can pass through concrete walls and structures (30m through 2 internal tilt slab walls). However, the XT Hive fitting just needs to reach its closest neighbour on the same network security key to establish communications.

-

How do you secure the network to prevent HIVE fittings communicating with neighbouring buildings/systems?

When HIVE fittings are installed and powered up they automatically build their own network using a factory default network key. In the unlikely event that separate installations are installed side by side fittings may temporarily communicate with those in an adjacent site. This is remedied when the register is uploaded assigning a location reference to each fitting. Each site will then use/assign a custom network key to “lock down” the network and networks keys are unique to a building/site.

-

Can the service pin (test button) be used to send a message from a fitting back to the server?

Yes. You can also communicate directly to each fitting on the floor at the individual device using the Mobile Bridge device.

-

How can HIVE communicate to Emergency lights in RF restricted areas?

If a site contains an RF restricted area (eg Faraday cage) An HIVE-DATA (HIVE-to-Wired) conversion module can be used to communicate via data cable to fittings within the restricted area. All fittings will still be visible as part of the HIVE Network. Fittings with remote gear are also used in this type of application and in this case the control gear could be placed outside the RF restricted area and therefore remain as an HIVE fitting.

-

What is the maximum distance achieved between a HIVE controller and a fitting?

Technically, approximately 200m in open air and 30m/2 walls inside a building, but this becomes irrelevant as the HIVE controller only needs to connect with the closest HIVE fittings and it won`t be 200m away. The HIVE platform uses DSM meshing to create our network – not point to point to the furthest fitting on site as some other systems attempt to do.

-

How many floors can the signal travel through?

HIVE uses DSM meshing rather than Gateway to each fitting (point to point) technology. This means HIVE fittings only need to communicate with the next emergency fitting IE the floor above or below. This means the question on distance of travel (how many floors?) becomes irrelevant.

-

Does the HIVE signal interfere with Microwave sensors?

No, The HIVE RF frequency will not disrupt a microwave sensor signal

-